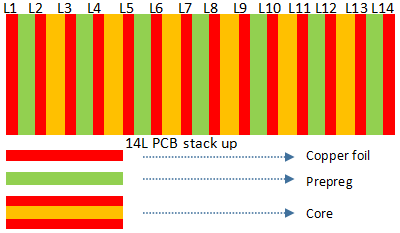

Standard 14 layer PCB stackup options

Our standard 14L layers stackup is the most common options selected by most PCB designers. The standard 14 layer stackup can be utilized in most applications for multilayer PCB board. As the standard options, you can get a variable 14 layer stack up from Weller’s engineering suggestion, which is defined by following with 3 options … Continued