Quick Turn PCB Manufacturing

The key to delivering quick turns is every part of the organization from order entry to shipment working as a team. Our world class front-end engineering (CAM) systems and processes coupled with our rapid response manufacturing enable us to delivery on time and on-budget.

We have developed the ability to provide quick turns for all the technologies that we manufacture. 30% of our business is quick turn and we can tool 40 – 50 new part numbers a week. We know that you can count on us to deliver good quality boards on time, every time.

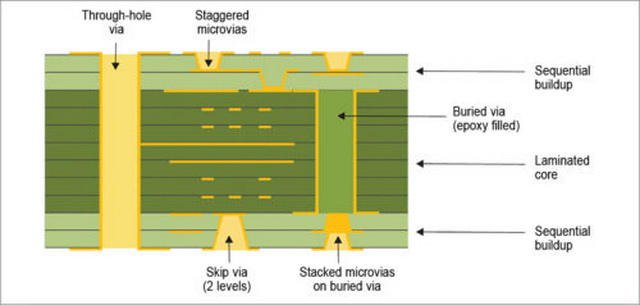

HDI PCB Manufacturing

Our HDI capabilities include laser micro-vias, blind and buried vias,stacked-via holes, fine lines and spaces, sequential lamination, via-in-pad technology. We have provided microelectronic pcbs with fine pitch devices down to 200 microns, using 50 micron laser drilled via-in-pad technology and thin build-up materials. Upload your data and receive a free consultation and review of your HDI PCB design today or contact us if you need any design help. Experience our expertise and feel the difference.

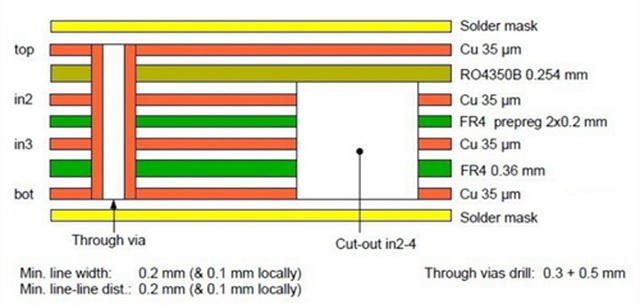

Hybrid PCB Fabrication

Our experience allows us to provide our customers with most comprehensive service in complex circuit board production for these products as we have invested in, such as Hybrid PCB(FR4+Rogers) fabrication.

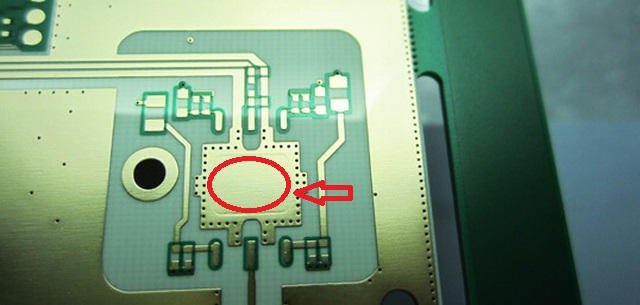

Copper embedded Coin PCB Fabrication

If your product application need your PCBs for high-power components, a built-in cooling feature can be very important for keeping your PCB from overheating. Coin insertion technology for PCBs can be an extremely effective solution for thermal management. When it comes to embedded coin thermal management solutions, some of the most popular options are Embedded T-Coin, Embedded I-Coin and Embedded C-Coin. Our rich experience of manufacturing embedded-copper-coin PCB can well support your power design.

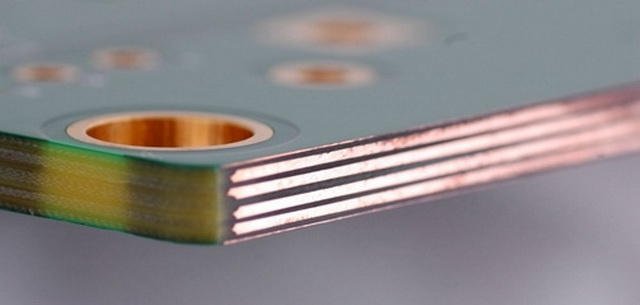

High Current and Heavy Copper PCBs

Weller has more than 15 years of experience crafting heavy copper PCBs. The units take more care than other types of circuit boards because of the thermal resistance presented by thick copper plates. Heavy copper PCBs handle higher rates of current than other boards, are able to resist higher temperatures for longer amounts of time and provide for stronger connection points. We manufacture units with copper components from 3 oz/ft2 to 8 oz/ft2. Contact Weller for more information on Extreme Copper PCBs if you require more than 8 oz/ft2.

High CTI PCB board manufacturing

CTI (Comparative tracking Index) means A measure of the electrical breakdown properties of an insulating PCB laiminate material. It is used for electrical safety assessment of electrical apparatus(such as washing machine PCB board). Rating can be seen below.

| Tracking Index (V) | PLC |

| CTI>=600 : (S2126,S3116) | 0 |

| CTI: 400 to 599 | 1 |

| CTI: 250 to 299 | 2 |

| CTI: 175 to 249 | 3 |

| CTI: 100 to 174 | 5 |

| CTI: <100 | 5 |