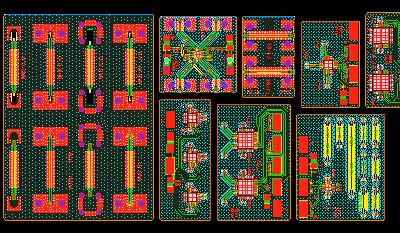

How to design couple of different PCBs in one panel

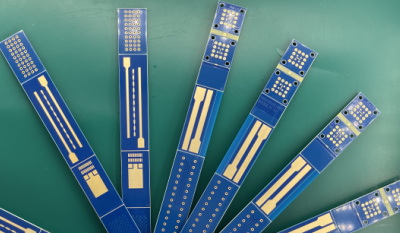

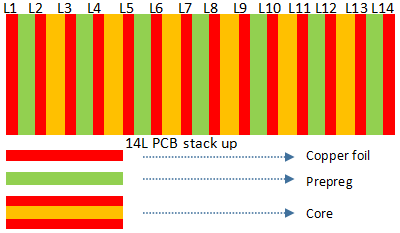

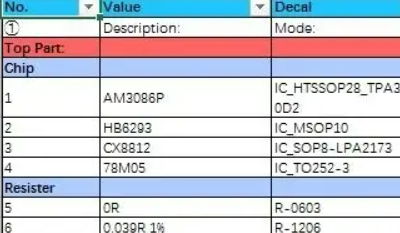

Optimize the global manufacturing cost of PCB and PCBA prototypes When it comes to start a PCB design for prototypes, Most circuit board designers like to put various PCBs (the same layer count and stack up but with difference in size, shape etc) into one panel to optimize the cost in the PCB fabrication and … Continued