Quote Within 24hours

Weller Technology is a full turnkey solution provider for all types of PCBs and PCB assemblies. We are dedicated to supporting your project with our integrated capabilities from PCB fabrication, components sourcing, PCB assembly and testing & programming to final product assembly.

Free DFM Checking

Upload Files NowQuality & Service

Always You Can Trust

Comply With

IPC 6012 CLASS 3/3A

Certificated By

ISO13485:2016

Certificated By

ISO9001:2015

Certificated By

IATF16949:2016OUR SERVICES

Since 2006, Weller Technology is an electronic solutions company offering PCB layout & PCB fabrication, testing & validation of high-reliability Flex, rigid-flex, RF/Microwave, HDI, high layers and high complex rigid printed circuit boards.

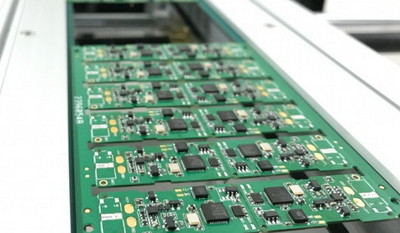

From 2010, Weller Technology has started to focus on PCB assembly service in the field of industrial control, IOT system, military, automotive, communication and telecom, etc. With 6 SMT lines in house today to provide a "one-stop-shop" and all in-house solution with 100% responsibility towards its customers

New Product Development

A full range of engineering support is available to assist you to get your new products to market quickly with the right functionality and at the right cost.

Manufacturing Service

We provide Electromechanical Assembly, PCB Assembly, Cable & Harness Assembly, Plastic Injection Molding, Plastic Thermoforming and Tool Manufacture from a global footprint.

Rapid Prototyping

Our team is keen to assist you with DFM and DFT input during prototype builds.

Supply Chain & Logistics

We have developed global supply chain and logistics solutions that minimize your costs and provide you with a highly resilient turnkey materials service.

OUR ADVANTAGES

Weller has been in the field of printed circuits board fabrication and it’s assemblies for over ten years, and accumulated our advantages compared to local suppliers abroad and offshore suppliers in China, so we have been always keeping serving our clients by European quality with Asian cost.

Instead of traditional simple business model that "order+payment+manufacturing+shipping", We do consider as a better business model that the combination of reasonable cost and added value in the additional services provided to our global clients, which are improving our competitiveness on the market and supporting us to establish best business model for each customer. As we do understand competitive pricing and stable quality is a basic "must" in today’s challenging environment, so we are constantly optimizing ourselves and enlarging our scope of services provided to our clients, our most valuable partners. The basic benefits and analysis of offered services in the below table shows our differences from other suppliers.

Followed by competitors

We are not the best one in china PCB fabrication and assemblies fields,but our team has been keeping proving us by diligent work on technology development,and taking the high alert to the tendency change and potential challenge from the market and report to our customer accordingly. More or less that we can have a bit proud that our ideas and actions followed by some competitors.

Reasonable Cost

We do not want to promise lowest cost as we do not expect that customer receive the products that they can not use it. As most of the low cost products is from inferior grade material, low investment in manufacturing equipment and poor skilled workforce, this will generate the low cost of manufactured products but unstable quality. All cost quoted at Weller is strictly evaluated by our understanding to customer’s final product’s reliability and quality guaranteed accordingly.

No MOQ

No minimum order quantities. No matter it is PCB fabrication or PCB assembly, you can conveniently order as small as 1pcs, also you can order as large as thousands of PCS from us. Why should you risk a huge investment in stock when you can buy small quantities and freely reorder it as needed? By this flexible term you do not worry any sensitive shelf life material, you can order it at any time when you need it.

Free DFM

Don't let the flaws on your design lead the failure in the manufacturing process. All your orders will be thoroughly reviewed by our experienced and skilled technicians via latest engineering software platform to detect out the potential bugs or errors, even it can reduce the manufacturing cost by the work of optimizing the "complex" and “high density” design.

Advanced Capabilities

As a one-stop electronic contract manufacturer, not only that we utilize the most advanced manufacturing techniques and equipment for various high precise PCB fabrication such as HDI,microwave,backplane, high-frequency radio frequency, and, our precision SMT assembly technologies can fully support fine pitch components as small as 8 mil pitch, passive components as small as 01005 package, Ball Grid Arrays (BGA) as small as 0.2mm pitch with AOI & X-Ray inspected placements.

100% Quality Guarantee

Based our knowledge and understanding to electronic manufacturing field, all our PCB fabrication and PCB assembly process are scientifically schematized, no any “economize” process like other “quick delivery” supplier operated. And, all materials we used are 100% certificated by UL, with the qualification by ISO9001, ISO13485, and IATF16949, which enable us have confidence to promise real one year warranty on our product and 100% refund if any failure taken due to us.

Definite Liability

More or less part of our quality policy is prevention in all business activities and manufacturing steps. Although having good quality results, we still has a large sense of liability and using various tools to protect our clients. Today the industry is a large field with various of supply channels, from the bottom ones up to the first class suppliers and our mission is to work with clients closely on quality questions at any step of the manufacturing process, from design up to manufacturing and market after sales. Strategic and long term partnership can not be built without full trust and liability coverage, and Weller is proud for its performance towards our partners.

Flexibility

Flexibility is very important in electronic manufacturing filed. This mainly focused on 3 core points, reaction time, lead time and capacity. We are able to be 7X24 hours available for urgent issue. Regarding lead time, we have both QTA (Quick Turn Around) production and normal production to meet the customer’s lead time needs on different cost basis. About capacity, we are always keeping an average free capacity as a supplement for potential urgent demand order.

Professional Support

Weller staff is combined from professionals with long term experience and skills, the supporters on some key positions are from an experience from the first class worldwide manufacturing companies. We have been presenting our activities in IPC, CPCA, SPCA and other worldwide recognized associations,which is strengthening our quality level in all aspects of the business. Our advanced manufacturing capability and professional support may be very helpful support to your success. The detailed pre-study of each project case is securing stability and guarantee for each project case we enter into with our partners.

One stop solution, High mix, Low volume

Generally,very most manufacturing facilities is just focusing on one type of boards due to the limitation of manufacturing capability or investment capacity. However, at Weller, you can make everything happened, no matter it is conventional PCBs or high density multi-layer circuit boards; no matter it is quick turn or standard lead time, or it is rigid or FPCB or rigid-flex, we provide bare boards as well as integrated services for electronic manufacturing, such as box building assembly, design or OEM etc.

Experience and Reputation

Weller is recognized as a supplier into high class electronic industries, gaining constantly its reputation. Being qualified by some OEM car manufacturers, medical and industrial products manufacturers, our goal is to always keep studying and working hard to improve ourselves to be awarded from more clients.

Safety Stock/Consignment

Due to the demand for new technology and electronics continues to grow, shortages and component obsolescence are commonly becoming an increasingly large threat to OEMs and EMS providers everywhere. In addition, seasonal changes in customer demand can also suddenly lead to a greater need for goods. However, very often Weller always keep high alert to the electronics market, and is accustomed to keep some crucial components in stock for our long-term cooperation customer to mostly reduce the risk or the shortage or price increasing up.

On time and safety delivery

We can do the on time delivery, because:

- We regularly stock some special laminate raw material such as heavy copper thickness,high Tg,high frequency material, etc.

- We regularly stock over 5000+ common electronics components parts;

- We use information and alert system to monitor and collect the demand information from electronic parts markets;

- We have professional sourcing team to work with world famous electronic components distributors. Further more, our engineering teams can help customers resolve sophisticated technical issues.

Payment Terms

Based on our internal analysis system, we are able to offer open accounts with excellent conditions to those clients that can meet our transaction requirements, from the start of the business. This service is bringing significant advantage to the mutual business, helping to build trustful cooperation.