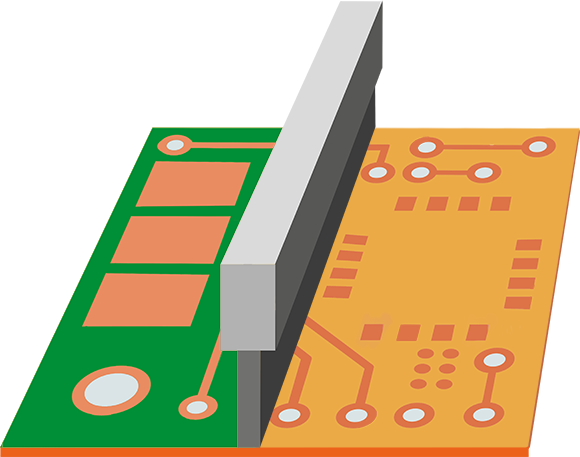

Soldermask ink is coated over the whole PCB surface. By using artworks and UV light we expose certain areas to the UV and those areas not exposed are removed during the chemical development process – typically the areas which are to be used as solderable surfaces. The remaining soldermask is then fully cured making it a resilient finish.

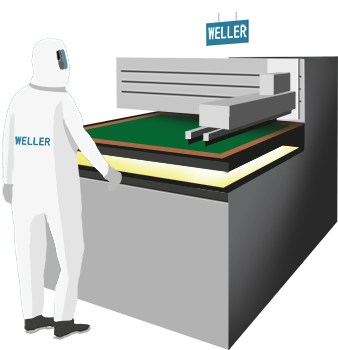

This step of the process is performed in a clean room.

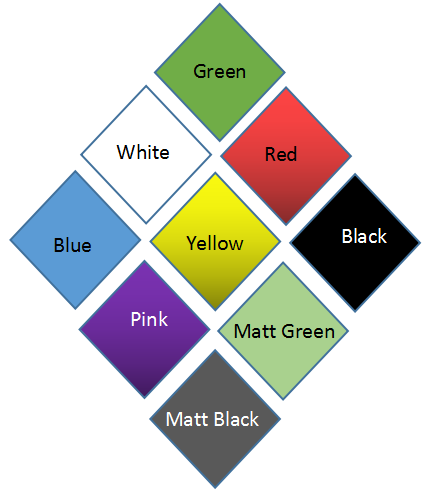

Common PCB silkscreen color: Green, black, white, blue,yellow,pink,red,matte green, matte black.

The primary purpose of the mask is to restrict the areas that will be covered with solder. It also protects panels from contamination, handling damage and possible electrical shorting during assembly and installation.

Importance: With ≥ 5um on the knee of the track and between 10-30um on the surface. The thickness of solder mask is critical to improved electrical insulation and resilience to chemistry or mechanical force that could cause loss of soldermask.

At WELLER,we always keep using high quality of soldermask material such as Taiyo-PSR-4000 to print the PCB board.