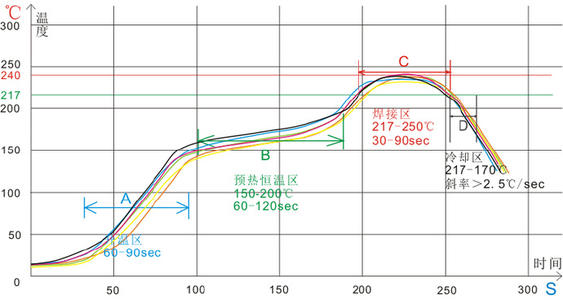

Reflow soldering is an important part of assembly process by which the molten state solder paste will turn to the permanent solder joints. So as that the SMD components is soldered on the SMT pad of the bare printed circuit board.

After this process, the components has been fully soldering jointed with it’s SMT pad under them.

In Weller, we are using latest 12 temperature zones solder reflow machine to ensure the high quality soldering performance, especially for some fine pith and high density BGAs. And, all production record of soldering profile is kept 1 month at least for available traceability unless spherical request from customer. Which is better than other suppliers who do not have any production record backup.