PCB assembly process is based on the production data of PCB design and specification of PCB fabrication. Excellent PCB design will facilitate subsequent PCB assembly processing, while incomplete design will affect the processing process and even affect the quality of the final PCB assembly product. So what are the PCB design factors that will affect PCB assembly processing? Here is some common issues that circuit board designer need to have an attentation.

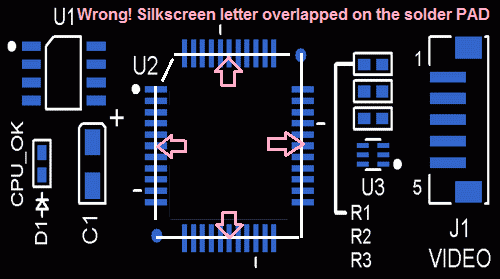

1. There should be no silk screen on the soldering position.

The silkscreen on the SMT PAD will affect the assembly quality (preventing the solder ability).

However, sometimes the silkscreen mark of some critical ICs is necessary due to that it can be used to identify the deviation of solder quality (especially for some high precious QFN components),so the IC’s edge mark can be put the corner of the SMT area to avoid any overlapping issues to soldering PAD.

2. The minimum distance between copper foil and board edge is 0.5mm, the minimum distance between component and board edge is 5.0mm and the minimum distance between pad and board edge is 4.0mm.

3. Necessary of Fiducial mark and Tooling holes:

Fiducial mark (red arrow in below picture) is necessary to be placed in single PCB or panel. It is used on assembly machines as the reference position for a paste printing machine or a pick-and-place machine to ensure a precise electronic components soldering operation in the PCB assembly process. … Normally the minimum diameter of a circular fiducial mark is 1.0 mm with 3.0mm solder mask opening area.

Tooling holes (pin arrow in above picture) also is a non-plated hole, which is with normal size 3.0mm with quantity of 3pcs at least to be placed on the circuit board. This is use to fix the Printed circuit board for not freely movement during PCB in the production process such as electronic test process or outline profile process. This is necessary holes for convenience to PCB fabrication and manufacturing process.

4. When designing the double-sided board, pay attention to the components of the metal shell. When the shell is in contact with the printed board when DIP, the solder pad on the top layer cannot be opened, and it must be covered with solder mask oil or silk screen oil.

5. Do not place the jumper track under the IC, motors, potentiometers, or other components with large metal shells.

6. Electrolytic capacitors can not touch heat-generating components, such as high-power resistors, thermistors, transformers, radiators. The minimum distance between electrolytic capacitors and radiators is 10 mm, and the interval between other components and radiators is 2.0 mm.

7. Large components (such as transformers, electrolytic capacitors with a diameter of more than 15mm, sockets with large currents) should increase the pad.

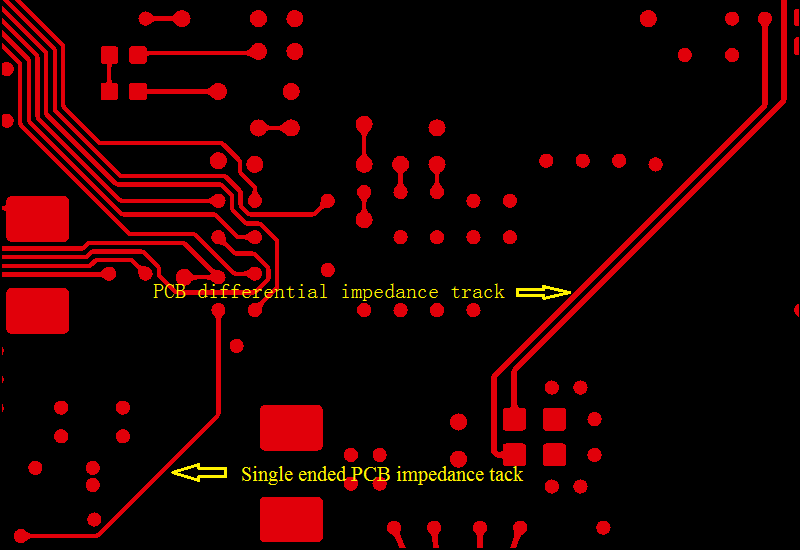

8. The minimum track width/spacing: 0.1mm/0.1mm; it will take extra challenge to PCB fabrication capability and it’s manufacturing cost will raise up accordingly if the track width/spacing less than 0.1/0.1mm. Of course, if your final electronic product is a high integrated circuit design and has the limited physical size to PCB board, you have to consider less track width/spacing and the manufacturing cost is at a reasonable range.

9. There should be no copper foil (except grounding required) and components (or as required by the structural drawing) within 5mm of the screw hole radius.

10. The pad size (diameter) of the general through-hole mounting component is twice of the hole diameter. The minimum of the double-sided board is 1.5mm and the single-sided board is at least 2.0mm. If round pads are not available, waist pads can be used.

11. If the center distance of the pad is less than 2.5mm, the surrounding pad should be wrapped with silk screen oil, and the width of the silk screen oil is 0.2mm.

12. For components that need to be soldered through the tin furnace, the pad should be opened away from the tin position. The direction of the pad is opposite to that of the tin, which is 0.5mm to 1.0mm. This is mainly used for the back-welded pad in one side to avoid blocking when passing the furnace.

13. In the large area PCB design (more than about 500cm or more), in order to prevent the PCB board from bending when passing through the tin furnace, a 5mm to 10mm gap should be left in the middle of the PCB board without components (can be routed) to be used to add bending bars to prevent bending when passing through the tin furnace.

14. In order to reduce short circuit of solder joints, all double-sided vias do not open solder mask windows.

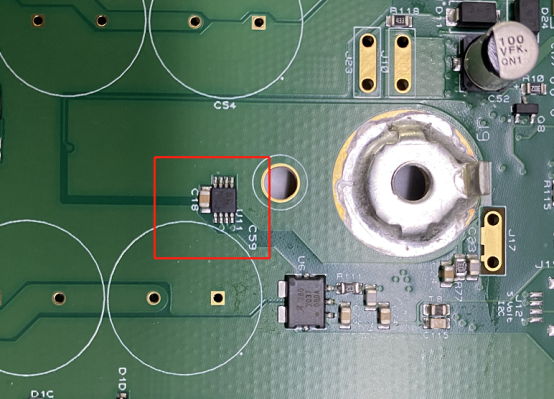

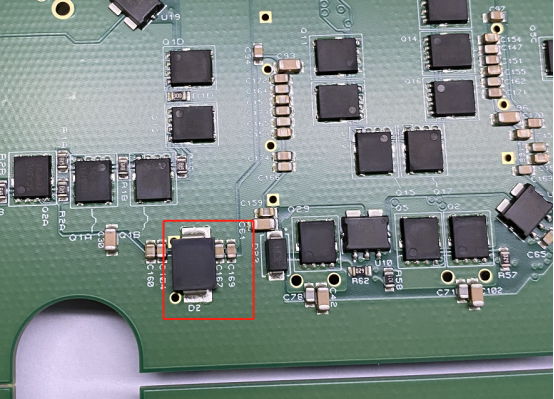

15. Keep enough physical spacing between SMD components or through hole soldering components, or else to avoid any potential edge-overlapped issues, which will take extra trouble to SMD assembly process(the deviation soldering issues).

The above items is some PCB design factors that affect PCB assembly processing, if you have any other engineering questions please feel free to send your concerns to our email: [email protected],we will response within 24 hours.