Today the world is changing fast with new technology development, especially PCB manufacturing technology that plays an important role in the application of LED circuits boards. These are widely used for many applications such as home, interior vehicle, and commercial applications, etc.

LED is short for Light-Emitting Diodes. Which is semiconductor light sources that combines by two primary polls (P –type and N-type) : P-type semiconductor (larger hole concentration) with an N-type semiconductor (larger electron concentration).

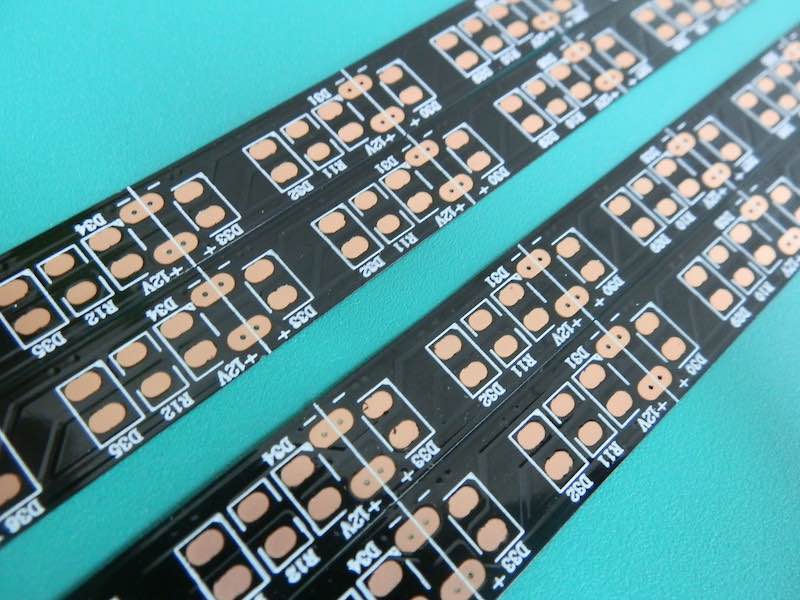

LED PCB is a type of printed circuit board that to assemble the LED chips on. It can be designed as through holes type of SMD type by metal base material, normally is Aluminum or Copper clad.

LED Printed Circuit Boards

The conventional light sources generated by this steps: first convert electrical energy into heat, and then into light; the latest LED technology realize it by directly converting electrical energy into light, so the heat in this process need to be eliminated as much as possible.

Therefore, the circuit board that has the LEDs assembled on plays an important role that to dissolve the heat. So as that the material of aluminum was an ideal raw material that used to manufacture LED PCB board.

The main reason is that Aluminum has the perfect ability to conduct heat and efficiently dissolve the heat that other material can’t do. The LED circuit board has a thin layer of aluminum that keeps working just the other PCBs do. Also, it has a thin layer of non-electric material that can well help to reduce the heat pressure and work as a thermal conductor. So it has a lot of advantages compared with that using FR4 base material circuit board to assemble the LEDS on.