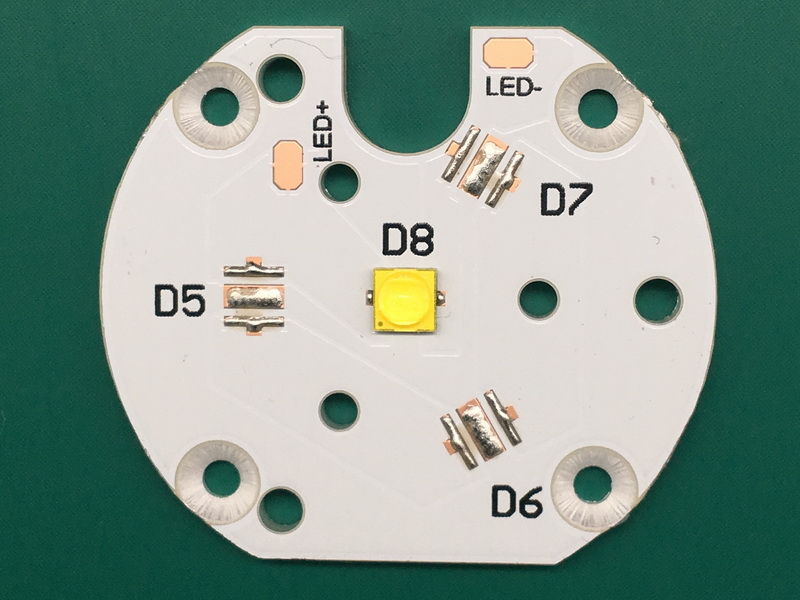

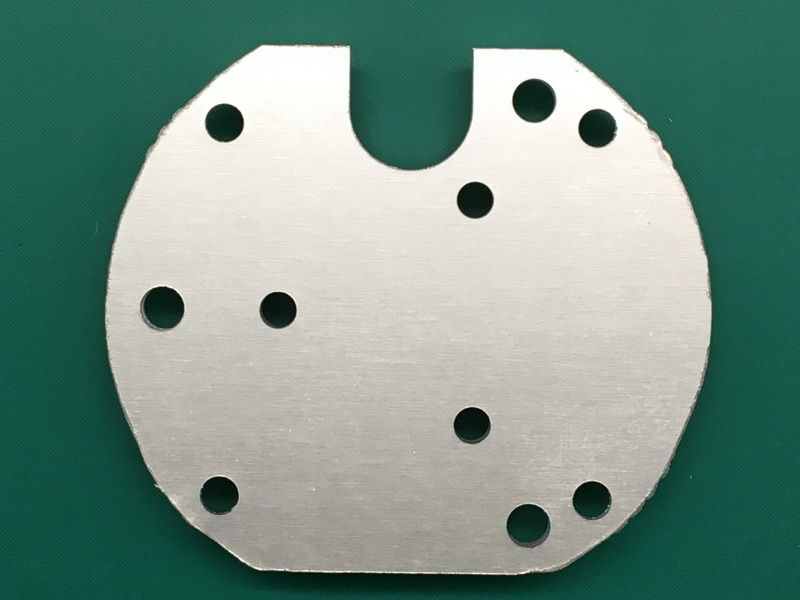

With it’s excellent feature of Aluminum thermal dissipation, Aluminum is a type of ideal metal base material for circuit board which need thin dielectric thermally conductive as well as electrically protected layer. This kind of PCB is widely used in the electronic devices such as LED lighting for consume products, automotive field, etc.

Due to it’s similar feature as copper base PCB board, aluminum base material can be used as a metal base core in the stack up of hybrid PCB production.

It can be used in the RFI (radio frequency interference) PCB board as an ideal dielectric thermally conductive layer, as well as electrically protected layer.

Advantages of Aluminum PCB Board?

Harmless to Environment:

Aluminum is very friendly to environment and recyclable metal. Less chemical manufacturing process than FR4 PCB board because of its simplicity feature of “bonded” together with a copper layer.

Heat dissipation:

High temperatures and serious hot take harmful to electronic device, even to degrade the working performance of the hardware. So it is useful to utilize a material that can help disperse the heat. Aluminum can really absorb the heat from the vital segments, by this manner limiting the hurtful impact it could have on the electronic circuit board.

Higher Strength:

Aluminum can provide extra quality and strength to a feature that fiberglass or ceramic bases can’t. Aluminum is a strong rigid base material that can diminish unexpected breakage during electronic device assembling, taking care of, and regular use.

Lighter weight:

For its extraordinary strength, absolutely aluminum is a shockingly light weight metal compared with other materials such as copper, steel, etc. Aluminum includes advantages of strength and quality without including disadvantage of any extra weight.

Widely Application of Aluminum PCB

More and more electronic devices’ PCB designed as metal circuit board with aluminum core based. The universal application areas for aluminum PCB board include:

- Surgical Lighting Tools in Medical Care

- High-power Scanners machine

- Tail Light Assemblies in Automotive or Airplane

- Distributed Power Transmission Systems

- Dashboards of Automotive

- High Power Converters

- Consume Lighting

- Theatre Lighting in Medical Operating

- Landscape Lighting

- LED Industrial Light

- High Bay Light

General Characteristics of Different Aluminum Material

| Performance | Units | 1100 | 3003 | 5052 | 6061 | 2024 |

|---|---|---|---|---|---|---|

| Density | g/cm³ | 2.710 | 2.730 | 2.680 | 2.700 | 2.78 |

| Melting Point Range | ℃ | 643 – 657.2 | 260-510 | 607 | 585 | 502 – 638 °C |

| CTE(linear 68°F) | Um/m. k | 23.6 µm/m-°C | 23.2 µm/m-°C | 23.8 µm/m-°C | 23.6 µm/m-°C | 23.2 µm/m-°C |

| Specific Heat Capacity | J/kg-k | 904 | 893 | 880 | 896 | 875 |

| Thermal Conductivity | W/m. k | 222 | 162 | 138 | 151-202 | 121 |

| Electrical Conductivity | %IACS | 59 | 50 | 35 | 47 | 50 |

| Electrical Resistivity | n Ω. m | 30 | 34 | 49.3-49.9 | 32.5–39.2 | 58.2-60 |

| Rigidity(hardness) | HB | 23 | 28 | 61 | 95 | 137 |

| Elongation at Break | (1.6mm)% | 15-28 | 28 | 25 | 12 | 19 |

Note: Dielectric breakdown for PCB laminates is usually tested upon IPC TM-650 test method 2.5.6 for breakdowns across the material and test method 2.5.6.2 for breakdown through the material; i.e., layer to layer.

Aluminum Substrate Properties

| Item | Performance Index (Measured value) |

|---|---|

| Peeling Strength (n/mm) | 1.8 |

| Breakdown Voltage (vdc) | 2 k |

| Thermal Conductivity (ω/m-k) | >0.8 |

| Dielectric Loss Angle (Tangent) | 280°C / 260°C, 1 minute, no bubbles and lamination |

| Dielectric Loss Angle (Tangent) | 0.03 |

| Combustibility | FV-o |

| Dielectric Constant (1mhz) | 4 |

| Thermal Resistance (°C/ω) | <1.2 |

| Insulation Resistance (ω) | 1*10 g |

Metal PCB with Bergquist Thermal Clad Base

Bergquist is a famous brand and well known as it’s thermal management insulated metal Substrates. It’s Aluminum PCB laminate MP-06503 has minimize thermal impedance and conduct heat more effectively than standard printed wiring boards (PWB’s).

This substrate is more mechanically robust than thick-film ceramic and direct bond copper construction. Due to it’s excellent feature of enabling optimal performance and extending device lifetime,Hence, this is almost an ideal material to most electronics designer for their high quality thermal application products.

| Item | Value | Test Method |

|---|---|---|

| Product Thermal Conductivity | 2.4 W/m-K | MET 5.4-01-40000 |

| Dielectric Thermal Conductivity | 1.3 W/m-K | ASTM D5470 |

| Thermal Resistance | 0.09°C-in2 /W (0.58°C-cm2 /W) | ASTM D5470 |

| Thermal Impedance | 0.65°C/W | MET-5.4-01-40000 |

| Glass Transition | 90°C | ASTM E1356 |

| Max Operating Temp. | 130°C | U.L. 796 |

| Max Soldering Temp | 325°C | U.L. 796 |

| Item | Value | Test Method |

|---|---|---|

| Dielectric Constant | 6 | MET 5.4-01-40000 |

| Dissipation Factor | 0.003/0.017 (@1KHz/1MHz) | ASTM D5470 |

| Capacitance | 410 pF/in2 (65pF/cm2) | ASTM D5470 |

| Volume Resistivity | 1×1015 (Ω•m) | ASTM D257 |

| Surface Resistivity | 1×1014Ohms-cm | ASTM D257 |

| Dielectric Strength | 2800 V/mil (112 kV/mm) | ASTM D149 |

| Breakdown Voltage | 8.5 kVAC | ASTM D149 |

| Item | Value | Test Method |

|---|---|---|

| Color | White | Visual |

| Dielectric Thickness | 0.003″ (76 µm) | Visual |

| Peel Strength@25C | 9 lb/in (1.6 N/mm) | ASTM D2861 |

| CTE in XY/Z Axis | 40 µm/m°C | ASTM D3386 |

| CTE in XY/Z Axis >Tg | 110 µm/m°C | ASTM D3386 |

| Storage Modulus | 12/0.3 GPa (@25°C/150°C) | ASTM 4065 |

| Item | Value | Test Method |

|---|---|---|

| Water Vapor Retention | 0.21% wt. | ASTM E595 |

| Out-Gassing Total Mass Loss | 0.29% wt. | ASTM E595 |

| Collect Volatile Condensable Material | 0.01% wt. | ASTM E595 |

| Item | Value | Test Method |

|---|---|---|

| U.L. Maximum OperatingTemperature | 130°C | U.L. 746B |

| U.L. Flammability | V-0 | U.L. 94 |

| Comparative Tracking Index (CTI) | 0/500 (425) | ASTM D3638/ IEC60112 |

| Solder Limit Rating | 300°C/60 seconds | U.L. 796 |

| Benefits of Bergquist Thermal Clad Metal Core PCB |

|---|

| Thermal resistance 0.09°C in^2/W (0.58°C cm^2/W) |

| Thermal conductivity of 2.4 W/m-K |

| Multi-Purpose applications |

| lead-free solder compatible |

| Eutectic AuSn compatible |

| RoHS compliant and environmentally green |

| Available on all aluminum and copper metal substrates |

What is Your Best Choice for Aluminum PCB Service?

For material, if your final electronic product is only for consume application purpose, the common aluminum base material is enough for that and would be cost saved;if your final product is a complex application require high quality such as military,aerospace products, Bergquist aluminum thermal clad would be a good reference but cost is too hight.

For the aluminum PCB manufacturing and PCB assembly, At WELLER, we have a well-prepared staff, a committed R&D group, a skilled engineering team, and cutting-edge setup. These basic foundations enable us to have the manufacturing capability to produce the aluminum PCB completely upon your requirements. We even can make uniquely custom aluminum PCBs according to your needs.

Contact us at any time in case you have any inquiries or you need an evaluation for an aluminum PCB fabrication and assembly.