The purpose of PCB surface finishing is to ensure the good behaving of printed circuit boards solderability and it’s electrical function. The original copper prefer to live in the air by oxidizing material instead of it’s original copper.So the PCB copper surface (SMT PAD,soldering PAD,etc) need to be protected from oxidizing.

The normal PCB surface finishing is 8 options as below:

| 1. HASL – Tin/Lead hot air solder level |

| HASL or HAL, means hot air solder level,which is a type of finishing usedon printed circuit boards (PCBs). The PCB is typically dipped into a bath of molten solder so that all exposed copper surfaces are covered by solder. Excess solder is removed by passing the PCB between hot air knives to avoid the soldering shortage. The typical application of the HASL is in Automotive PCB products, Military PCB products. Typical thickness 1 – 40um. Shelf life:12 months Note: As Heavy metals LEAD contained in the soldering material,so HAL surface finishing can not meet RoHS compliance as harmful substance lead contained with non-environmentally friendly. |

| 2. OSP/Entek-Organic solderability preservatives |

| OSP also called Preflux, which is a method for coating of printed circuit boards. It uses a water-based organic compound that selectively bonds to copper surface and protects the copper suface from oxidizing until soldering. It’s a low cost surface finishing but a bit sensitive and not so robust aHAL. The typical application is consuming electronics products such as electronics toys products. Can comply with ROHS directive. |

| 3. Electroplated nickel gold |

| It is a typical finishing that coating the nickel on PCB surface before plating the gold. The purpose of the coating nickel is to ensure the diffusion between gold and copper. There are 2 options of Electroplated nickel gold: Hard Gold Plating: bright,smooth and hard surface,robust, element of cobalt contained. The application is for contactors (pin),or the places used for electrical connection. Soft Gold Plating: Pure gold but not right surface. The application focuson bonding process of IC package. Can comply with ROHS directive. |

| 4. Immersion gold |

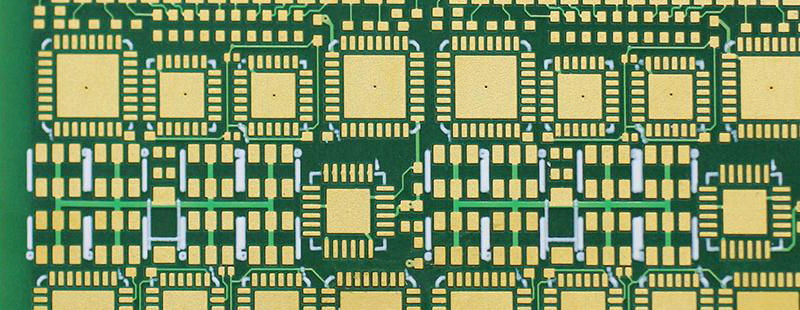

| Aslo called ENIG ( Electroless Nickel / Immersion Gold): which is a two layers of metallic coating (2-8 μin Au over 120-240 μin Ni) on printed circuitboards. The Nickel is the barrier to the copper and is the surface on which the components are actually soldered to. The gold protects the nickel during storage and also provides the low contact resistance required for the thin gold deposits. ENIG is now arguably the most used finish in the PCB industry due to it’s good features of lead free assembly. |

| 5. Immersion Tin |

| Immersion Tin (also called White Tin ) is a deposit of a thin layer of Tin coating on the Copper layer of a PCBs. It was not used as often as other surface finishes because not all PCB manufacturers offer it in the part years (before 2006) but now it is popular. The flatness of this particular coating makes this an ideal surface finish choice for small geometries and components. It is a RoHS compliant (lead-free) surface finish that is an ideal choice for flat surface requirements and fine pitch components. Note: it is can not be storaged as a long shelf life due to it’s weak feature of oxidizing. |

| 6. Immersion silver |

| Immersion silver is a type of PCB surface finish that applied directly coating on the copper surface of printed circuit boards. This material has a thickness of 5 micro inches to 12 micro inches specified by IPC 4552, and has a stable capability to last for shelf-life at least 12 months. This finish is most popular used for aluminum wire bonding, metallic dome contacts, and EMI shielding. |

| 7. ENEPIG(Electroless Nickel Electroless Palladium Immersion Gold) |

| ENEPIG is a type of surface finishing coating on the PCB copper layer to protect it from oxidation and corrosion. With it’s plating method uses Electroless Nickel, Electroless Palladium, and immersion Gold can improve the solderability of copper,and is also RoHS compliant. |

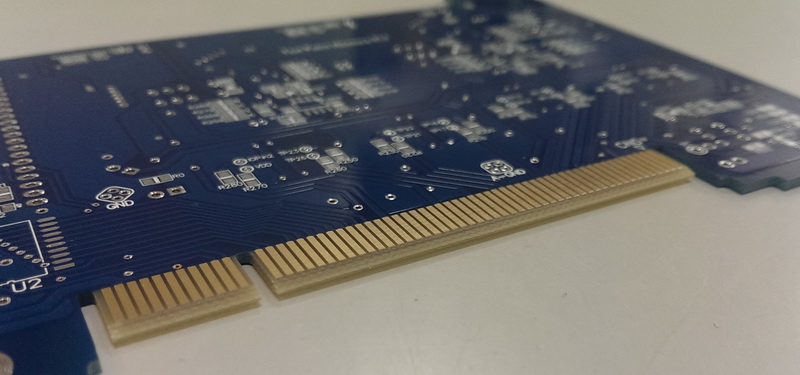

| 8. Hard Gold plating |

| Hard Electrolytic Gold is a type of PCB surface finishing consists of a layer of gold plated over a barrier coat of nickel. Hard gold has excellent durability, and is most commonly applied to high-wear areas such as edge connector fingers and keypads. Of course the cost is very high. |

Typically, the decisive factors when it comes to selecting the most suitable finish is the end application, the assembly process and the design of the PCB itself. If you need further or more detailed information, please contact us and we will be more than happy to answer any of your questions, for example that about:

The features of different PCB surface finishes ,and

How to choose the surface treatment process for printed circuit boards.