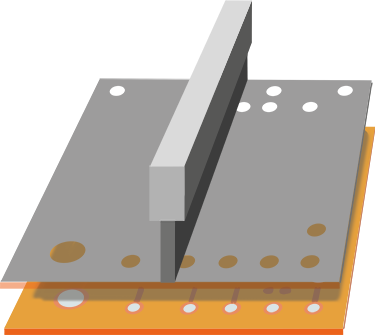

It is to plug the via holes by solder mask or by resin performed in a clean room.(Or fill the via holes with copper,which is another process).

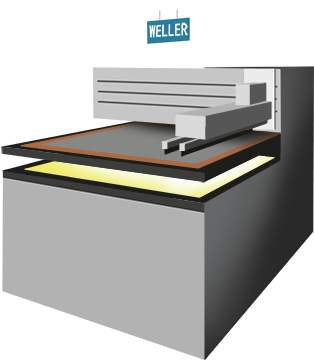

How to do this? By screen printing to push soldermask into holes – a separate operation using an aluminium stencil.

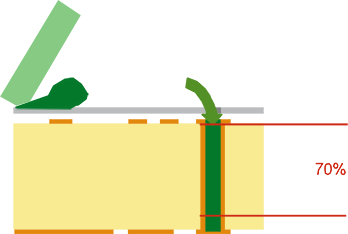

WELLER perform the plugging criteria with 70% filling per hole. This is to eliminate the risk of “broken” circuit path after high temperature in assembly process.