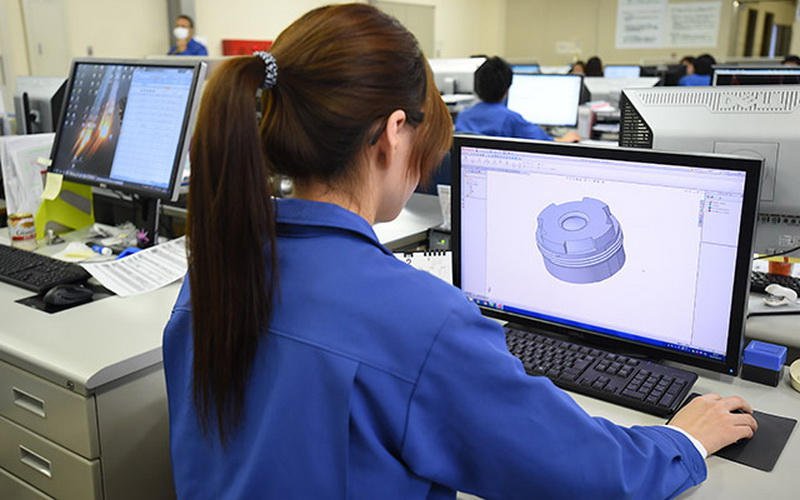

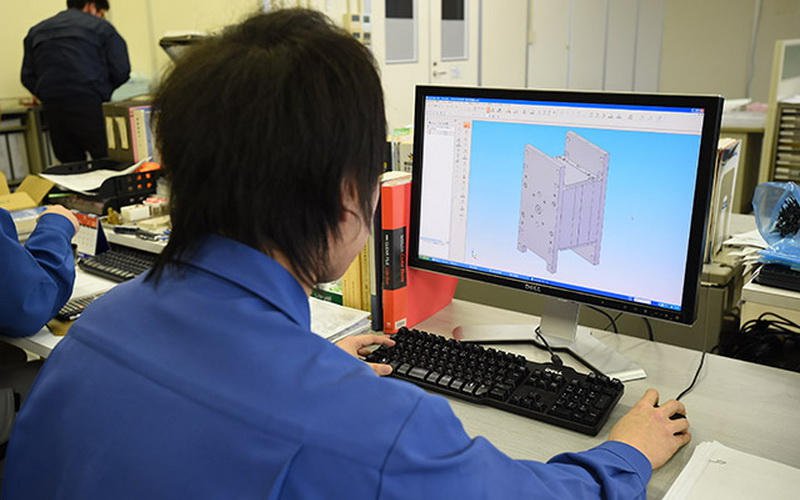

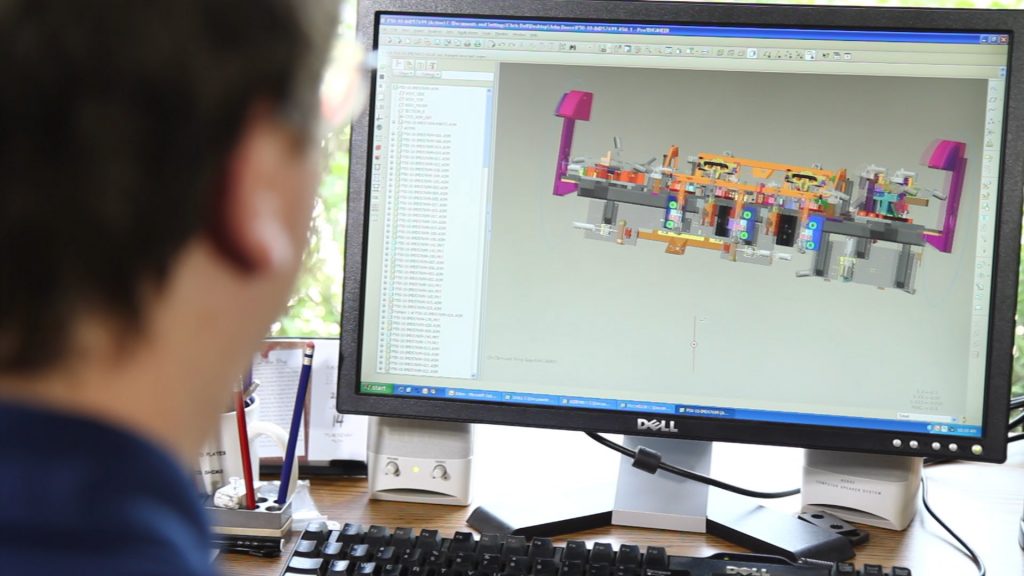

Mold Engineering Support

Our engineering design team analysis the structure of parts and provide mold technology plan and other factors for your confirmation before design CAD,2D,3D drawing ,including the specification of your machine, the future demand of annual capacity, material and so on, our design software have CAD,CAM, PROE and UG , to believe a perfect design will keep quality mold and improve efficiency of work, prevent possible production risks, we pay attention to every details and make sure the finished product get a satisfied feedback. Also we well know HASCO,DME molds and can provide mold flowing analysis for your reference.

Molding Department

Weller mold department have engineering department, product development ,CNC workshop, EDM workshop, wire cutting tooling center , polishing surface treatment, mold assembly and so on. We have all kinds of imported equipments to support the manufacturing of tooling and molding. we have rich experience engineering technician,pay attention to the quality of mold, take very step of mold manufacturing procedure seriously, control the efficiency and delivery for your project.

Mold capability: about 30 molds/month ,the precision of mold is plus-minus 0.02MM and the length of mold is 2000MM.

![]() Plastic molds

Plastic molds

![]() Injection mold tooling

Injection mold tooling

![]() Insert molding

Insert molding

![]() Injection production

Injection production

![]() Prototyping

Prototyping

![]() Technology support

Technology support

![]() Design assistance

Design assistance

Wire Walking Machine

VEDM

Precisison Grinding Machine

Mold Workshop

Mold Inspection

Injection Molding Workshop

High Speed CNC

Mirror EDM workshop

Mirror EDM workshop

CNC Workshop

Molding Quality

Quality assurance is an integral part of any company in today’s competitive marketplace, we take it very seriously. Also we are responsible for the quality of customers’project. we guarantee your mold for life and the quality for production of parts .That means there is no quantity limit for your project.

We have following procedure ,

1. we will inspect the dimension, surface requirement or assembly delivery T1 sample when mold have finished tooling, and then we have a inspection report to customers for check

2. Visual inspection carry out by our machine operators for every parts .

3. The parts will inspect once again by our QA personnel once very hour.

4. Functional inspection by engineering personnel assembly if customer requirement.