The right choice of a printed circuit board manufacturer can make or break the required function and quality of a PCB assembly. Read on to discover vital points on how to choose a PCB assembly company.

Introduction

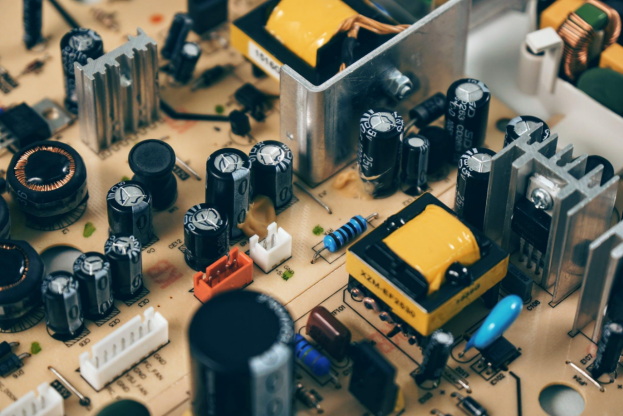

The culmination of the PCB manufacturing process is in the execution of the PCB assembly. This is the vital production phase that requires technical expertise and experience to implement. Therefore, it is crucial to engage a competent PCB assembly company, in the event of outsourcing, that would perform optimally. This can be challenging, due to the myriad of PCB assembly companies in the market. Contained in this blog are some essential guiding principles that will help you choose a reliable company for your printed circuit board manufacturing needs.

Always Do Thorough Research

Before deciding which company to work with, it is necessary to do thorough research to ensure that you have a deep understanding of the company. You cannot tell that a company is trustworthy just because of its low price, it’s more important to make sure they understand your ideals and standards. A reliable PCB assembly (PCBA) company would be able to work efficiently with the client and always adhere to their project schedule.

Determine the Experience Level

Experience is a another vital factor that should determine the choice of a PCB assembly company. An experienced company will inspire confidence and trust. This is because they have a professional team to ensure high-quality PCBA and fast turnaround time. To learn about the experience of a company, you can visit their website or talk to them directly about their assembly capabilities and project experience.

Ask evaluative questions like what kind of assembly services they offer, How many years they have been in the industry, and which clients they have provided assembly services to. With these questions, you can determine if a PCB assembly company’s experience matches your project requirements.

Find out the Company’s Scope of Services

Some companies offer other services in addition to PCB assembly, including the procurement of components, designing, supply chain management, and other related services. Dealing with such suppliers can save you the hassle of contacting several businesses to obtain various services.

Evaluate Service and Product Quality

This is another key factor that should be considered in picking a PCB assembly company. It may be difficult to determine the company’s output quality before producing boards with them, but there are ways to derive the necessary information without having to work with them first. You can do this by evaluating the following:

Material Sourcing: you can evaluate a company’s quality by looking at where its materials are sourced. Some manufacturers may sacrifice quality by sourcing materials from the lowest cost source, and as a result, the boards they produce may lack consistency, varying in performance from batch to batch. You need to ensure that your PCB manufacturer can deliver a standard and UL-approved circuit board.

Certification: To obtain industry certifications, companies must achieve high-quality standards and pass the third-party audit. Picking a company with certifications such as ISO9001:2015, ROHS, REACH, BSCI, and UL, would be the right decision.

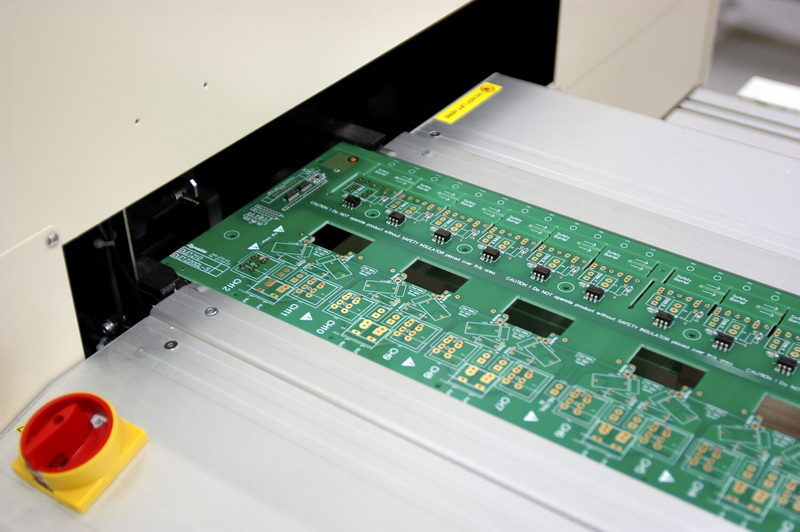

Equipment: a company is more likely to make quality products if they utilize cutting-edge equipment, so requesting the equipment list of companies on your radar is a good way to check.

Determine Production Capabilities

The production capability of the potential chosen PCB manufacturer should be considered in light of the number of circuit boards that a project requires. Companies that are focused on manufacturing huge quantities of PCBs for large production runs may not be able to support small quantities, and in the same vein, a small company only set up to undertake prototype PCBs or small production quantities may be hard-pressed to accommodate large orders. These requirements should align with the PCB manufacturer’s capabilities.

Check Customer Reviews

This is a good avenue for determining a company’s quality standard. You can get this information by browsing through the reviews on their website and social media, or by directly collecting feedback from their past and current customers.

Confirm Testing Services

It is vital to ensure the quality of PCBAs because poor-quality PCBAs can destroy your business and cost you a lot of money. To prevent this occurrence, it is important to inquire about the testing processes and methods used when choosing a PCB assembly company.

The goal is to select companies with stringent quality control systems and extensive testing protocols. This would assure you that your project will be taken through the array of tests that circuit boards require. These include functional testing, automated optical inspections, and visual inspections.

Compare Costs

The cost of PCB assembly is affected by many factors including order size, components required, shipping costs, labor costs, etc. It is good to save cost, but in comparing the prices of different suppliers, you should factor in their quality and other services, and then decide on the most cost-effective one to work with, without having to sacrifice quality.

Final Thoughts

Choosing the right PCB assembly company is a challenging but essential task for any PCB or electronics equipment manufacturer. The principles outlined in this article are a great way to figure out the right match for your manufacturing needs.

However, WellerPCB can help you achieve all of this without any stress.