High TG PCB board is typically defined as the high heat resistance in a PCB base material or a circuit board properly designed to withstand high temperatures operation process.

Generally,the High TG is means the PCB laminate’s Tg value greater than 170°C tested by IPC-TM-650 2.4.25D. Thus, a circuit board with TG greater or equal to 170°C is a high Tg PCB. When we talk about one of the most important properties of any epoxy, it is the Glass Transition Temperature (TG),normally it is typically specified in the material’s datasheet.

In addition, the Glass Transition Temperature is also the temperature point at which the polymer material melting from hard. At the glass transition temperature, the polymer material experience transition from rigid status to more flexible status making the temperature at the border of the glass-like to a soft rubbery state material.

Essentially, that high Tg PCB material has the property of flame-resistant; so it should not be brittle to heat or at a specific temperature; it can only become to be soft. The temperature point of the PCB board is called the Glass Transition Temperature (TG) therefore a high TG PCB is one of which the printed circuit board is made to have the capable of withstanding extremely high temperatures.

Also, during the layer lamination of PCB fabrication process, the higher the glass transition temperature point means the higher the temperature requirement in the manufacturing process. High-temperature requirements during lamination process will enable the boards to be crisp and hard, which tends to affect the electrical properties of the circuit board’s hole.

Nevertheless, normal PCB materials at high temperatures operation process will be subject to some phenomena like melting, flex and others, it’s electrical and mechanical properties would even degrade, too. Generally, base material Fr4 TG is around 130 – 140 Centigrade, high-TG is generically greater than 170 degrees whiles the middle TG is usually higher than 150-160 Centigrade. The performance of PCB moisture resistance, heat resistance, stability, chemical resistance, and other characteristics during High TG PCB manufacturing process mostly depends on how high the glass transition temperature it is.

FR4 (or FR-4) refers to the grade of Epoxy Glass laminate material, and TG refers to the glass transition temperature which is one property of FR4. When it’s melting point activated by an operated temperature, it merely means this temperature has exceeded it’s glass transition temperature value; hence the PCB plate material’s state will be changed from rigid to liquid, which in turn also affects the function of the Printed Circuit Board. The value produced is related to the stability of the PCB physical dimensions.

And, if one PCB with it’s base material’s glass transition temperature is greater or equal to a 170-degree, it can be specifically called high Tg printed circuit board (PCB). As a result of the rapid development and prompt upgrade of the electronics industry, high glass transition temperature materials today are widely used in communication equipment, military, nuclear energy, aerospace, and many other high complex applications.

What is FR4?

FR4 (or FR-4) is a designated code name from NEMA (National Electrical Manufacturers Association). The designation (FR-4) was created by NEMA in 1968. It stands for the grade of flame-retardant of fiberglass reinforced epoxy material. Therefore, FR4 PCB has as much higher level of resistance to heat than ordinary PCB.

However, this does not mean the FR4 material complies with the standard UL94V-0 unless testing is performed to UL 94.So, the PCB designer need to additionally specify the flammability resistance grade 94V-0 except base material FR4.

Basical characteristics of high TG PCB material

- Advanced High Tg Resin Technology

- Lead-Free Assembly Compatible

- Friendly Processing and CAF Resistance

- CAF Resistance

- Available in Variety of Construction

- high resistance to heat

- Lower Z-axis CTE.

- Excellent thermal stress resistance

- Excellent PTH reliability

- High thermal shock resistan

High-TG PCB Application

- Multilayer and High Layer PCB

- Automobile

- Backplanes

- Servers and Networking

- Telecommunications

- Data Storage

- Heavy Copper Application

Common materials used for high- Tg PCB manufacturing

- FR4 KB-6167F

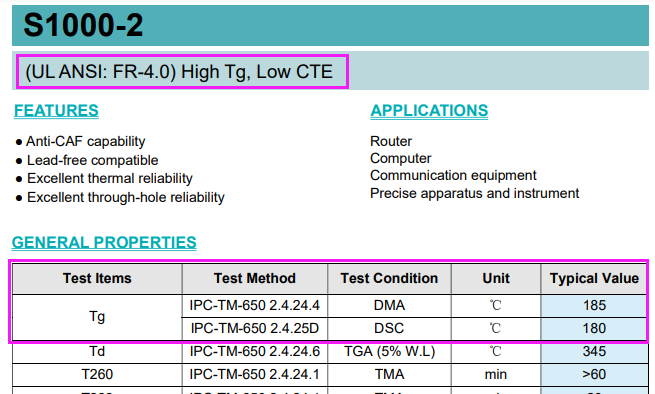

- FR4 S1000-2

- FR4 IT-180

- Rogers 4350B

| Material | KB-6167F | S1000-2 | IT-180 | RO4350B |

| TG (DSC, °C) | 175 | 180 | 180 | 280 |

| Td (WT, °C) | 340 | 345 | 345 | 390 |

| CTE-z (ppm/ °C) | 40 | 45 | 45 | 50 |

| Td260 | 60 | 60 | 60 | |

| Td288 (min) | 15 | 20 | 20 |

High TG PCB Manufacturing Capability of Weller Technology

| Layer Count | 1-30L |

| Board Thickness | 0.2-6.5 mm |

| Base material | FR4,Metal Core,Flex PI |

| Copper Thickness | 1/3-8OZ |

| Surface Finishing | HALS/HAL LF/ENIG/OSP/Immersion Tin/Hard Gold plating/Pre-flux |

| Solder Mask Color | Black./Red/Yellow/White/Blue/ Green/Pink/Matte |

| Silkscreen color | Black./Red/Yellow/White |

| Min. Hole Size | 0.1mm |

| Min. Line Width | 0.05mm |

| Min. Line Spacing | 0.05mm |

| Impedance Type | Single;Differential;Coplanar Waveguide |

| IPC Criteria | Class 2; class 3 |

| HDI Type | 1+n+1,2+n+2,3+n+3…any layer HDI |

| Back-drill | Available |

WELLER Technology keep provide manufacturing and assembly service for high reliability printed circuit boards more than 10 years.We have been alerted that technology in our industry is constantly evolving. Rather than becoming complacent, so we have been keeping pushing ourselves to further advance our technology capabilities and provide superior production service. We are driven to innovation in finding more cost-effective solutions that will reduce cycle times, optimize the price, and produce a better-quality product for our customers. By continuous investing in the resources of equipment and people, to achieve the goal that have our PCB assembly satisfies and exceeds its customer’s expectations. In terms of price, quality, and delivery.

If you are in the dilemma of looking for a trustable or reliable a high TG PCB manufacturer for your valuable products, look no further. You can use Weller technology to design your high TG PCB boards. No matter the complex nature and scope of specific PCB applications, the technical expertise at Weller technology will recommend you the best High TG PCB materials to develop a customized Printed Circuit Board (PCB) that would satisfy your particular demands.