High Frequency PCB is a type of electronic circuit board that particularly used for signal transmission in the variety of applications of electronic devices including mobile phone, microwave, radio frequency and other high speed design applications.

Due to it’s base material’s special features that has a frequency range of 500MHz – 100GHz, so the circuit boards manufactured upon this type of material are ideal choice to the electronic devices which have high-end applications such as: Cell phone,Telecommunications,Military and aerospace,RF microwave,Automotive (mainly LIDAR, which is a mini radar that communicates a vehicle’s surroundings),High-density interconnect and high-speed design applications.

Key Features of High Frequency PCB Boards

- They typically have a lower and stable Dielectric Constant (Dk) (ranges from 2.1 to 5) to prevent effectively signal transmission delay . The lower the Dk value, the higher the frequency transmission rate.

- They have smaller dissipation factor (DF) to avoid affecting the signal transmission rate. Therefore, it is more suitable f for faster signal propagation and low signal distortion.

- The circuit boards ensure the excellent thermal expansion rate of the laminates is the same as that of the copper foil. This feature will prevent the separation of copper foil once there is a temperature variation.

- Due to it’s feature of stable thermal structure, so the High-frequency PCBs can ensure appropriate thermal resistance, impact endurance, chemical resistance, as well as peel-off resistance.

The difference: High Frequency PCB or High Speed PCB?

In the topic of PCB industry, most people often confused by the phrase that “high speed PCB and high frequency PCB”.

Firstly, high frequency PCB must be a high speed PCB; but the high speed PC is not always a high frequency PCB. Why it is because of that:

High Speed PCB refers to a PCB which has to allow for transmitting data at a very high rate. So, it refers to the specific time domain.

High Frequency PCB refers to PCB which has to run the signals having high frequency and shorter wavelengths. So, it refers to the field of electromagnetic waves of the incoming and outgoing signals.

How to Select Material for High Frequency PCB

As the key feature “High Frequency” defines the PCB must work on the condition of High Frequency, so the base material must have an excellent performance of heat transmission. If the materials do not have this feature then it may take the accumulation of thermal stresses when the PCB works. Therefore, it is necessary to select such type of a material that has a favorable Coefficient of Thermal Expansion (CTE). In addition, the material should have high dimensional stability to avoid degrading while operating. Below are some core features of base material for High Frequency PCB:

• Excellent thermal and electrical conductivity: as the high frequency electronic devices usually requires advanced applications.

• Excellent moisture absorption resistance: due to the high frequency electronic devices usually apply to extremely complex environment.

• Smaller impedance tolerances: to reduce the sensitivity of High Frequency signals to noise.

P.S.: PTFE (Polytetrafluoroethylene) fromTeflon is the popular known material for high frequency PCB due to it’s excellent feature of low dielectric constant, high melting temperature, which can ideally replace the traditional FR4 circuit boards which have electrical loss. What’s more, it has excellent dielectric properties, especially at high radio frequencies which enable it to be suitable for use as an excellent insulator in printed circuit boards with it’s application at microwave frequencies (it is also used in connector assemblies and cables). Plus it’s highlighted feature of high melting temperature, this usually makes the material has the best high-performance that to replace the weaker and lower-melting-point polyethylene widely used in low-cost applications.

However, most of the base materials used in printed circuit boards are not pure PTFE but more or less have some small amount of micro-fiber glass impregnated into the substrate, or will be PTFE with woven glass reinforcement or ceramic filled.

Generally, and in comparison to the other types of high frequency base materials, the nearly pure PTFE without woven glass can be one of the most challenging type of circuit material to use in PCB manufacturing process.

The Application of High Frequency PCB

Nowadays, high frequency PCB widely used in most industrial applications.But, more and more electronic devices with high frequency PCB base interact with our daily lives. Such as ATM machine of a bank, a vending machine, the mobile phone, the smart phone such as I-watch, the drone plane, etc.

- Vehicle collision avoidance system,

- Satellite system

- Wireless communication system

- Unmanned Systems;

- Network communications

- Multimedia wireless communication base stati

Where and When to Go with High Speed Design?

Different fields of thoughts have different answers to this question. So there is no absolute or specific definition that tells us when and where to go with high speed design.

So, it mostly depends on your specific circumstances under that the electronic devices work. However, we have collected some following high frequency PCB design guidelines to PCB designers as a basic reference to them have it’s decision more easier.

- A high-speed design could be a good solution if the problems of signal integrity raised up in your PCB layout.

- Most experienced experts recommend to follow the device-specific-feature approach. Thus, if the electronic product you are designing is a cell phone, a motherboard, a DSL router, a communication base board, IOT tracker, etc. Then reasonably that you should look towards the high-speed design. But, this thought also suggests that once you have to integrity some interface ports such as USB, HDMI, SATA, or PCI express onto your PCB then you should again consider to go with the High Frequency PCB.

Talk Your High Frequency Project with Us

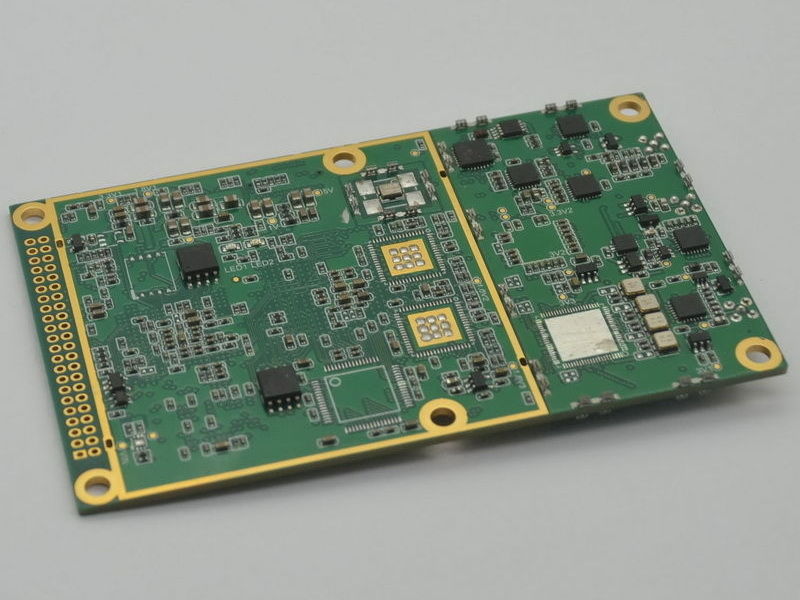

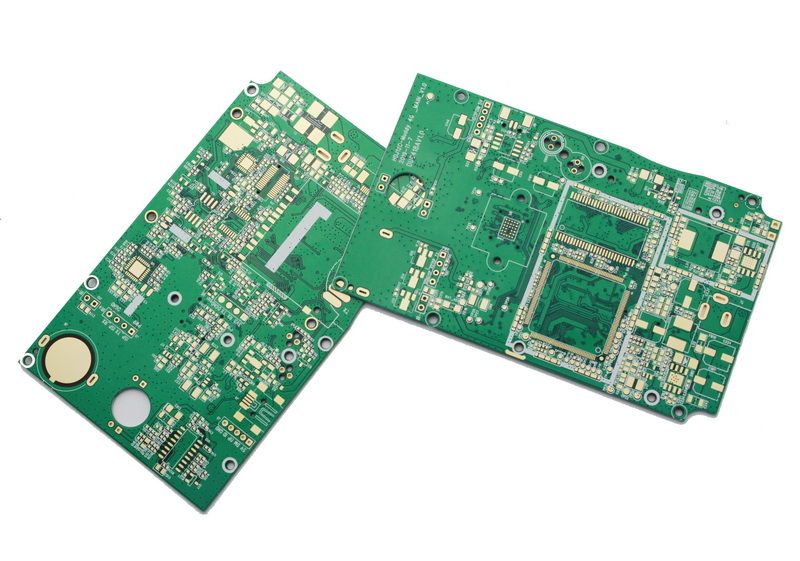

Weller Technology is a quality-orientation manufacturer with 10+ years’ experience in China.

Our team focuses on design and develop customized High Frequency PCB upon our customers’ needs. You can discuss with us about your any concerning on high frequency PCB project. We are willing to support our customer from start-engineering to end-manufacturing.